TOO HOT TO HANDLE

engineering 2016

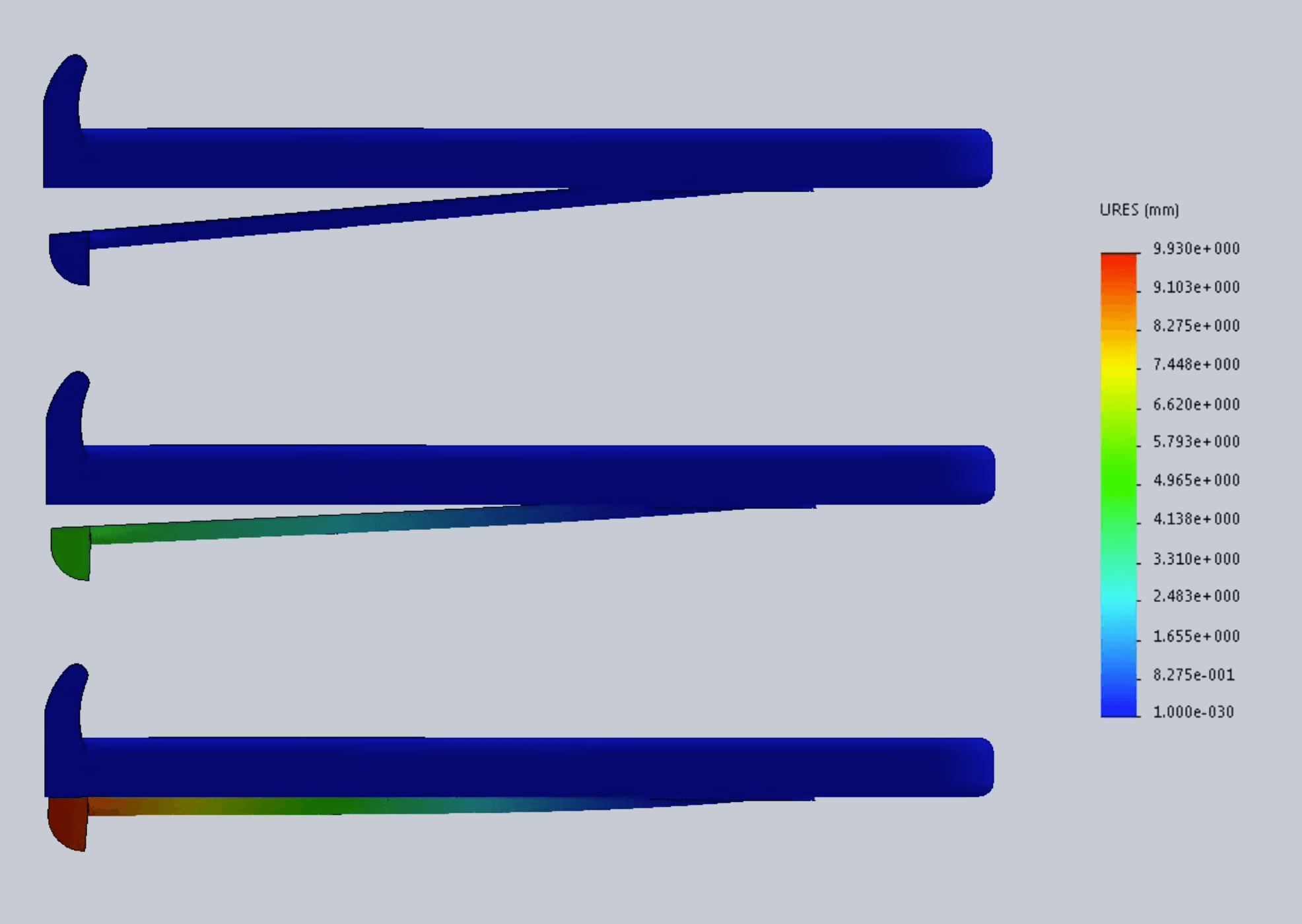

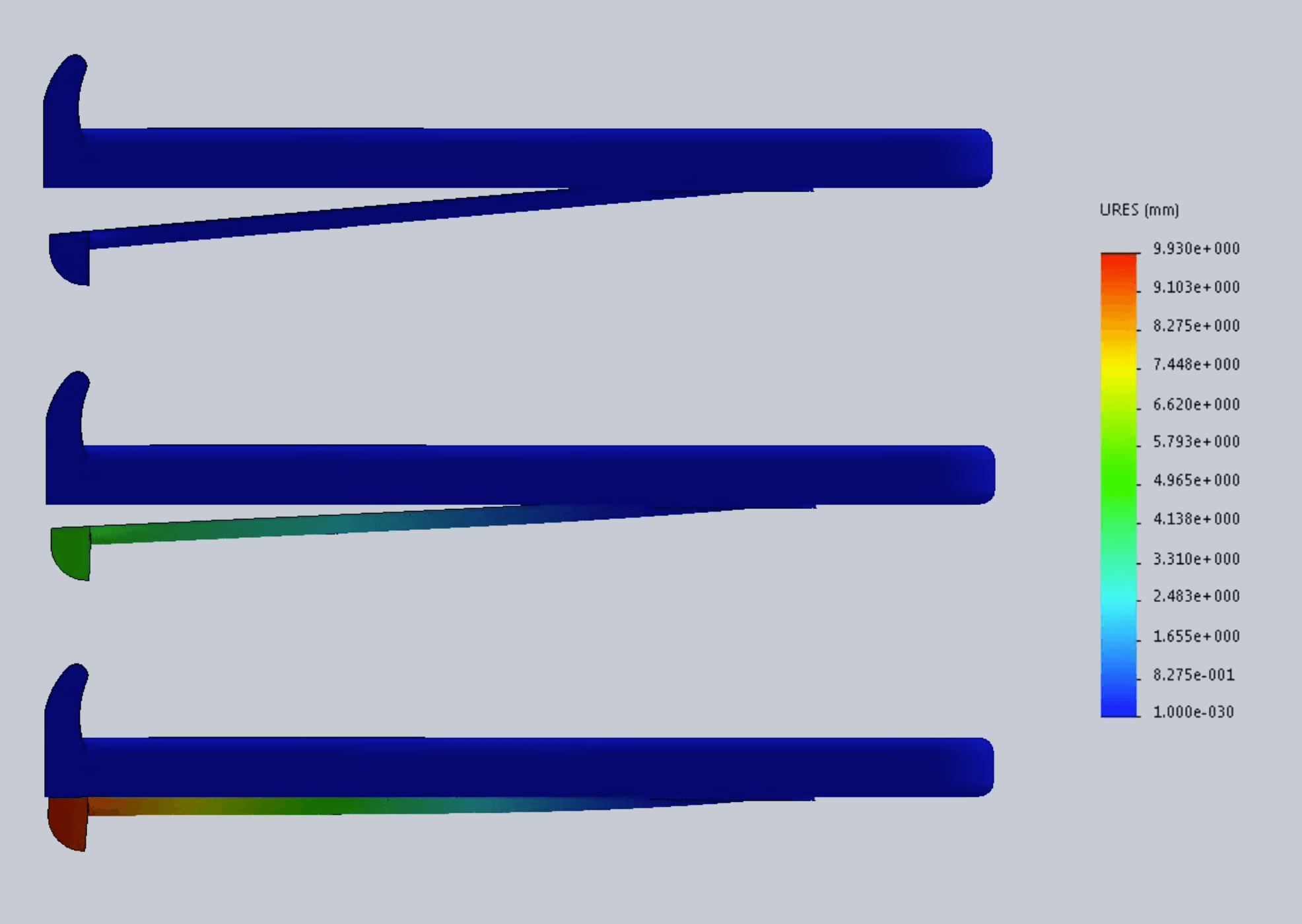

This project was created for a Mechanical Engineering class at UCSB. We were divided into groups of five and given about two months to run through the design process step by step. Our group was frustraited with pots and pans taking up a lot of valuable storage space due to their impractical storability.

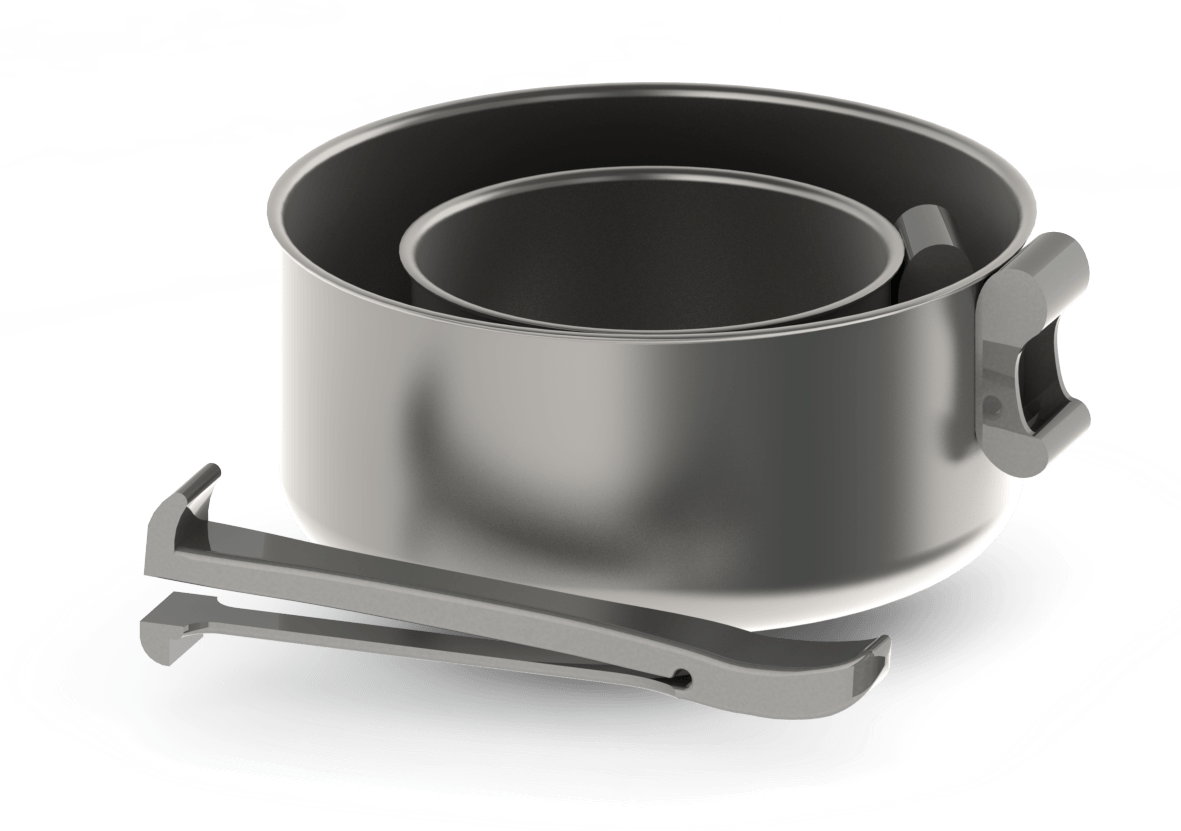

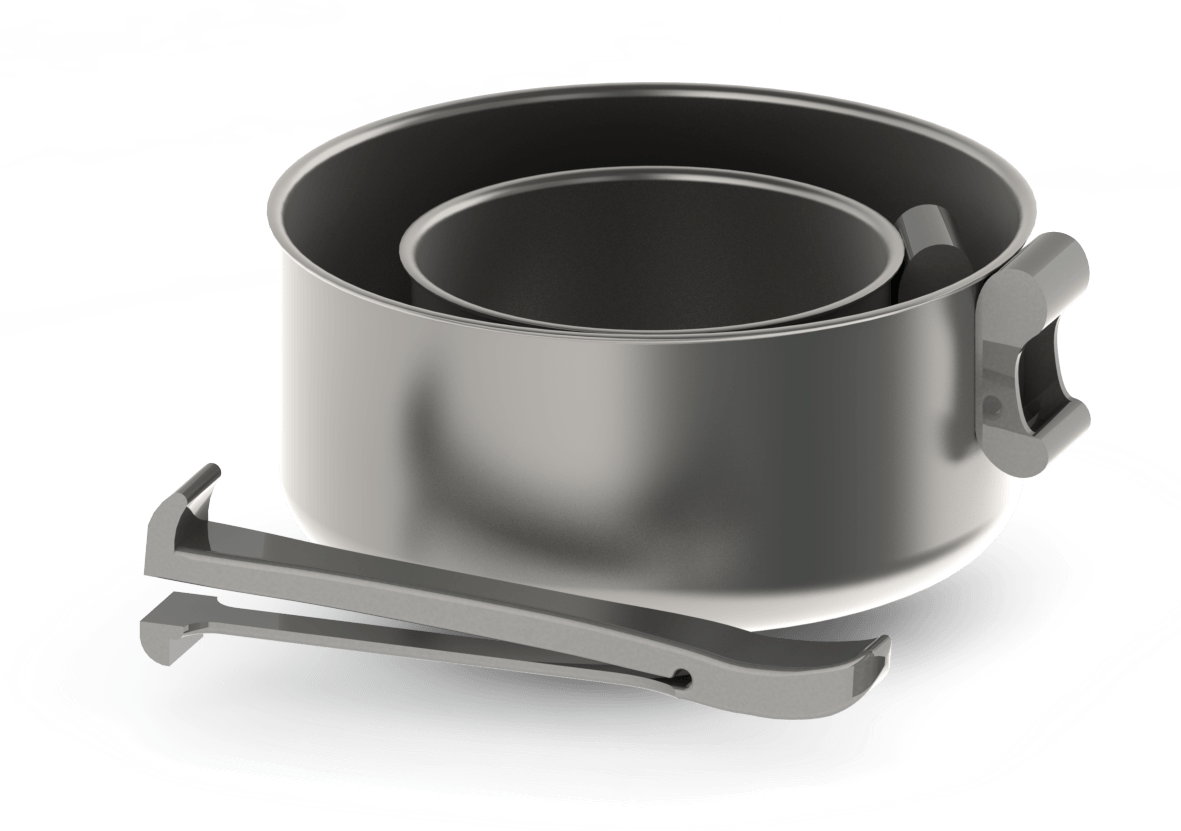

Pot and pan handles represent a considerable waste of space in a kitchen and can also be a safety hazard. By making the handle removable, we solve both of these problems, allowing pots to stack nicely within each other, and removing the chance of accidently knocking cookware off the stove.

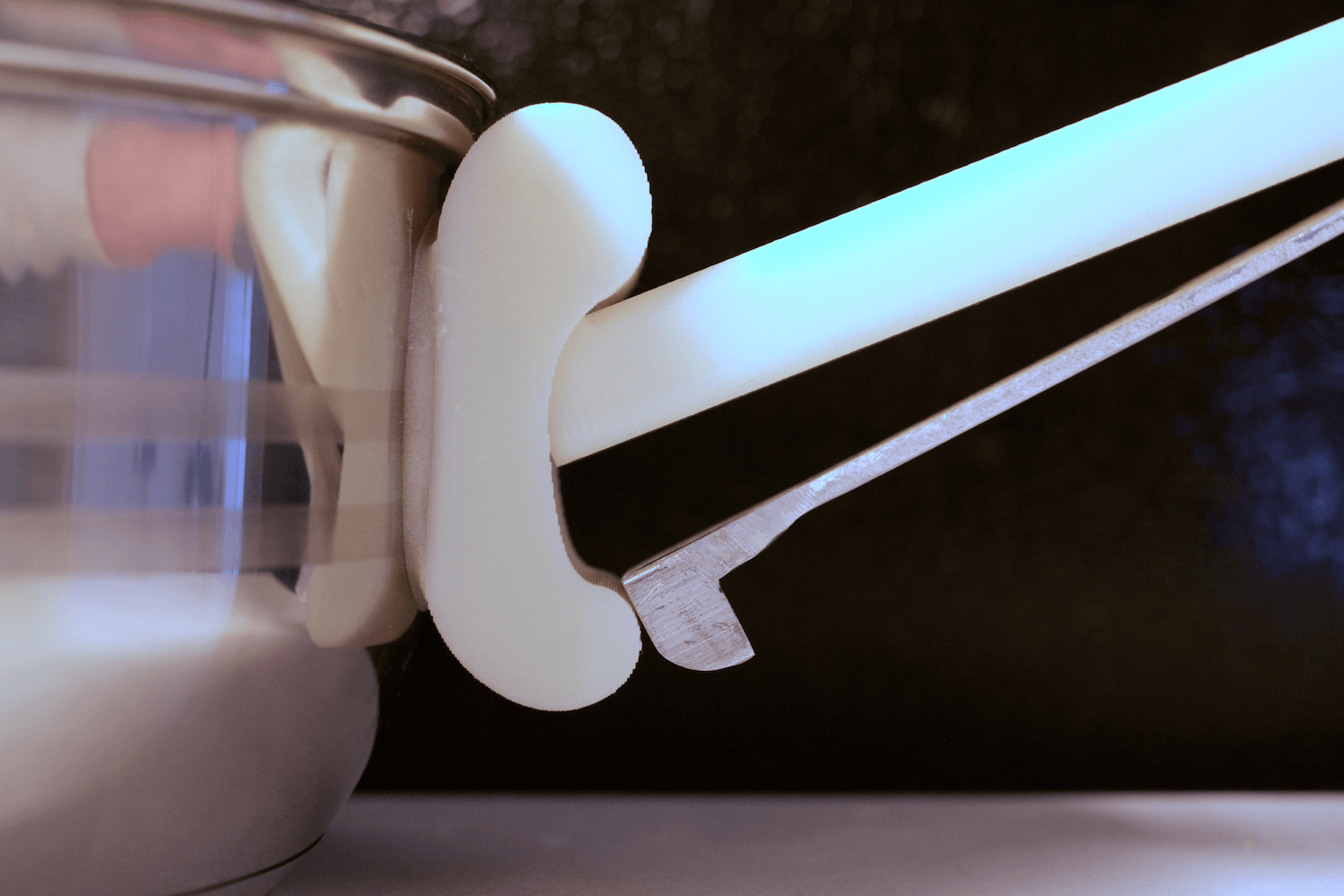

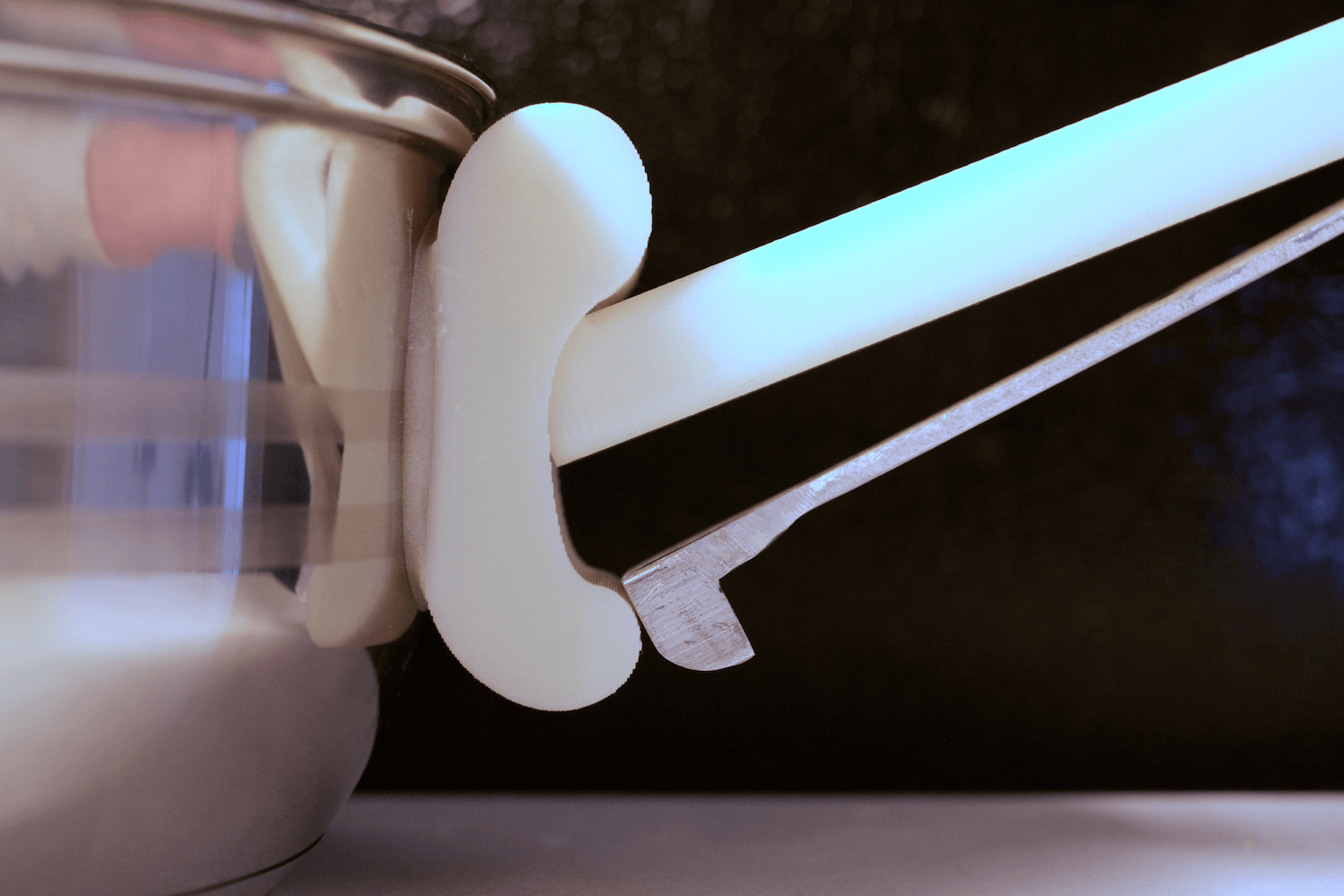

For our prototype (for simplicity of machining), the handle is made of two parts, the working part in aluminum, and the rest of the asembly is 3D printed in ABS plastic.

The set of pots with removable handle nests perfectly one inside the other to save space. And the handle clips on easily with one hand!

This project was created for a Mechanical Engineering class at UCSB. We were divided into groups of five and given about two months to run through the design process step by step. Our group was frustraited with pots and pans taking up a lot of valuable storage space due to their impractical storability.

Pot and pan handles represent a considerable waste of space in a kitchen and can also be a safety hazard. By making the handle removable, we solve both of these problems, allowing pots to stack nicely within each other, and removing the chance of accidently knocking cookware off the stove.

For our prototype (for simplicity of machining), the handle is made of two parts, the working part in aluminum, and the rest of the asembly is 3D printed in ABS plastic.

The set of pots with removable handle nests perfectly one inside the other to save space. And the handle clips on easily with one hand!